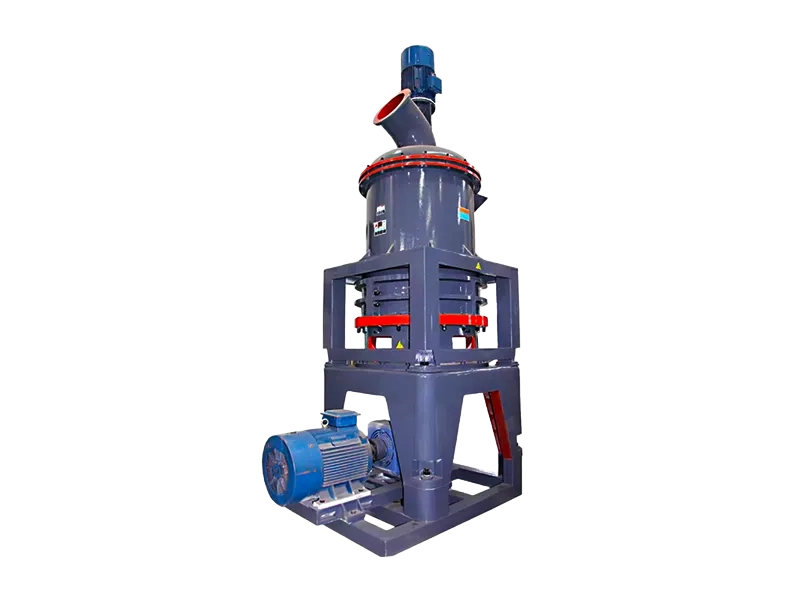

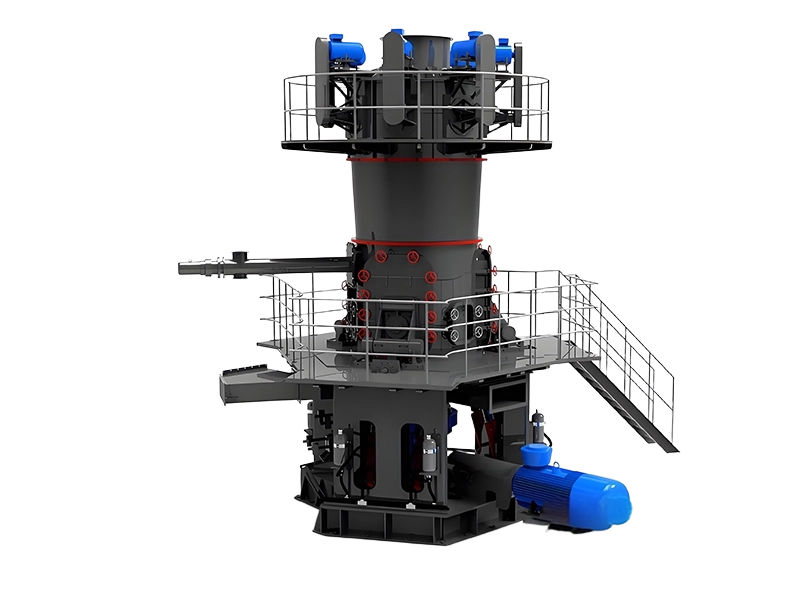

YGM High Pressure Suspension Roller Mill Materials

YGM high pressure suspension roller mill is suitable for limestone, calcite, dolomite, gypsum, barite, talc, quartz, marble and other materials.

YGM High Pressure Suspension Roller Mill Application

YGM high pressure suspension roller mill is widely used in the fields of building materials, chemical industry, mining, environmental protection, agriculture, fine chemicals and new energy materials for grinding various materials.

YGM High Pressure Suspension Roller Mill Features

High pressure and high efficiency

High pressure and high grinding efficiency.

Strong stability

Smooth operation, small vibration and low noise.

Automation

Electrical control, easy to operate.

YGM High Pressure Suspension Roller Mill Working Principle

- 1. Feeding and Grinding Area: The material enters the mill through the feeding device and enters the grinding area inside the main machine.

- 2. Function of Grinding Roller and Grinding Disc: The rotation of the main shaft drives the grinding roller to rotate on the grinding disc, and the material is pressed on the grinding disc. Under the action of gravity and centrifugal force, the material is ground into fine powder.

- 3. Air Flow and Classification: During the grinding process, the airflow generated by the fan discharges the ground powder from the grinding disc and is screened and graded by the grading device to ensure that the powder particle size meets the requirements.

- 4. Powder Collection: The powder that meets the requirements is sent to the powder collector through the powder discharge port to complete the grinding process.

- 5. Adjustment and Control: The working efficiency of the mill and the particle size of the output powder can be controlled and adjusted by adjusting parameters such as the feed amount, the gap between the grinding roller and the grinding disc, and the wind speed.

- 6. Safety Protection: The equipment is equipped with safety protection devices such as overload protection and temperature control to ensure safe and stable operation of the equipment.

Technical Parameters

| Model | Roller | Ring |

Feeding

Size (mm)

|

Finished

Size (mm)

|

Motor

Power (KW)

|

Capacity

(t/h)

|

Overall

Dimension (mm)

|

|||

|

Quantity

(piece)

|

Diameter

(mm)

|

Height

(mm)

|

Inner

Diameter

(mm)

|

Height

(mm)

|

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 18.5 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 37 | 2.1-5.6 | 7100*5900*7900 |

| YGM4121 | 5 | 410 | 210 | 1280 | 210 | 30 | 0.613-0.033 | 75 | 2.8-10.5 | 9200*7250*9700 |

| MTM160 | 6 | 440 | 270 | 1600 | 270 | 35 | 0.613-0.033 | 132 | 5-20 | 95500*8500*83500 |

| MTM175 | 5 | 520 | 280 | 1750 | 280 | 40 | 0.6-0.045 | 160 | 13-25 | 12275*9555*9916 |

“Twenty years of technology accumulation, is your reliable choice.”

— DingBO,DBM