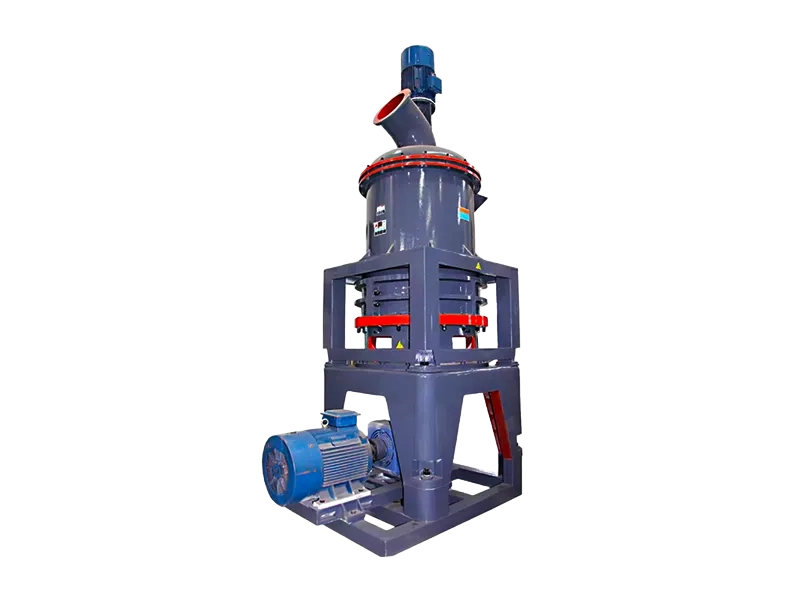

PC Coarse Powder Grinding Materials

PC Coarse Powder Grinding is suitable for grinding limestone, quartz, granite, calcium carbonate, coal gangue, iron ore, calcium stone, feldspar, talc and other materials.

PC Coarse Powder Grinding Application

PC coarse powder grinding is used in mining, building materials, chemical industry, metallurgy, coal, environmental protection, ceramics, glass and other industries.

PC Coarse Powder Grinding Features

High efficiency crushing

Large crushing ratio, fast crushing.

No Screen to Prevent Clogging

No screen is required to avoid clogging and run smoothly.

Environmentally friendly and closed

Closed operation reduces dust pollution.

PC Coarse Powder Grinding Features

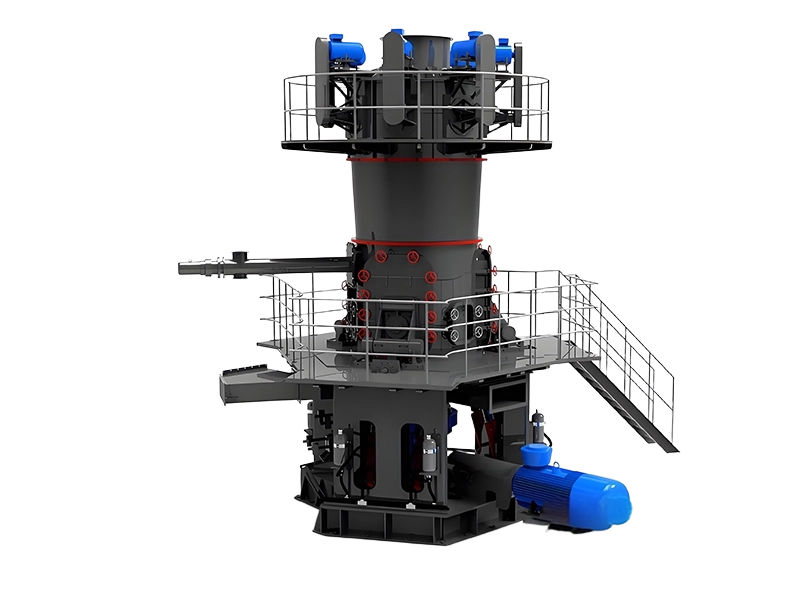

- 1. Material Conveying: Materials are fed into the interior of the mill through the feeding system.

- 2. Grinding Disc: The material is fed into the inside of the grinding disc, which is equipped with multiple grinding rollers. The grinding rollers rotate to grind the material. At the same time, the grinding disc is equipped with a grinding ring, which, together with the grinding roller, grinds the material.

- 3. Grading and Screening: The ground material is sent to the grading system, which screens the material and sends the coarse-grained material back to the grinding disc for further grinding, while the fine-grained material is screened out.

- 4. Collection and Packaging: The filtered fine particle materials are collected through a collection system and packaged through a packaging system to meet the different needs of users.

The vertical grinding machine achieves ultrafine grinding of materials through the rotation of the grinding disc and the grinding effect of the grinding ring and the grinding roller. At the same time, the equipment adopts a closed design, reducing the generation of noise and dust, which meets environmental protection requirements.

Technical Parameters

| Model | PC4008-75 | PC4012-90 | PC4012-90L | PC4015-132 |

| Rotor Diameter(mm) | 750 | 900 | 900 | 1150 |

| Rotor Length(mm) | 800 | 1200 | 1250 | 1500 |

| Rotor Speed(r/mm) | 800-1000 | 800-1000 | 960-1000 | 550-800 |

| Feed Opening Size(mm) | 320X930 | 400X1200 | 380×1450 | 500X1500 |

| Max Feed Size(mm) | <50 | <50 | <50 | <100 |

| Product Size(mm) | 0-3 | 0-3 | 0-3 | 0-8 |

| Processing Capacity(t/h) | 10-30 | 30-60 | 50-100 | 60-100 |

| Motor Power(kw) | 55-75 | 75-90 | 55-75*2 | 110-132 |

| Hammer Quantity(piece) | 18 | 32 | 40 | 32 |

| Dimensions(mm) | 2310 x 1665 x 1610 | 2840 x 2100 x 2020 | 3000 x 2600 x 2070 | 3720 x 2650 x 2540 |

“Twenty years of technology accumulation, is your reliable choice.”

— DingBO,DBM