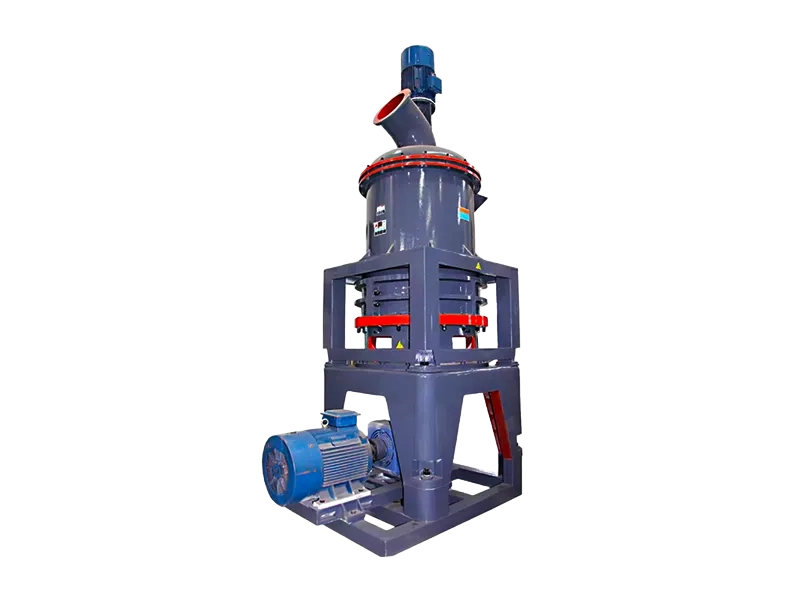

HGM Ultrafine Grinding Mill Materials

HGM ultrafine grinding machine is suitable for ultrafine grinding of non-metallic minerals such as calcite, limestone, marble, gypsum, calcium carbonate, etc.

HGM Ultrafine Grinding Mill Application

HGM ultrafine grinding mill is widely used in many industrial fields, mainly used for the production of ultrafine powder to meet the needs of different industries for fine materials. These fields include but are not limited to the deep processing of non-metallic minerals, building materials, chemicals, medicine, food, agriculture, environmental protection and new energy materials.

HGM Ultrafine Grinding Mill Features

HGM Ultrafine Grinding Mill Features

Efficient grinding

HGM ultrafine grinding machine adopts advanced technology to produce ultrafine powder quickly and efficiently.

Adjustable fineness

The grinding fineness can be adjusted accurately as needed to adapt to a variety of industrial uses.

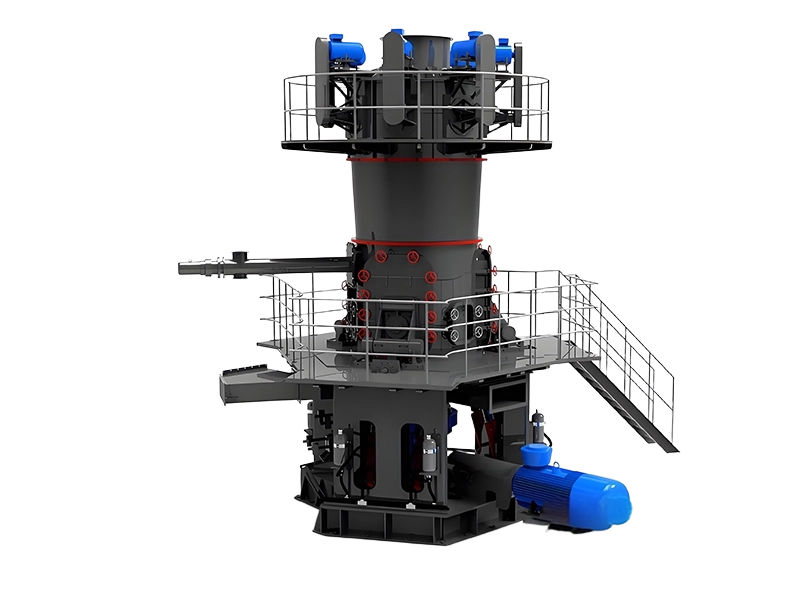

HGM Ultrafine Grinding Mill Working Principle

After hammer crushers break large bulky materials to smaller ones, elevator works to send materials to material bin. Next, materials are sent to the grinding mill evenly and they would fall onto the dispersing plate firstly. When the grinding mill runs, dozens of grinding rollers start to rotate and roll. Under the action of centrifugal force, materials on the dispersing plate are then thrown to the rim and drop to the grinding chamber. In the circuit, materials would be squeezed and ground. After being ground several times, materials are blown into the powder selector by airflow. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. Some remaining powders would be collected by impulse dust remover and they may stick to the surface of filler-bag. So, next, high-pressure airflow controlled by the impulse valve blows the filler-bag to make it swell and shake violently. This sudden shake can help kick off materials on the filler-bag and collect them as finished products. After filtering, the airflow would be discharged to the air. This system adopts an open circuit and runs under negative pressure.Technical Parameters

| Parameters of HGM Series Ultrafine Grinding Mill | |||||||

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Output Size (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-2000 | 150-1500 |

| Capacity (t/h) | 0.5-6 | 0.5-6 | 0.8-7 | 1.2-10.5 | 1.2-11.5 | 2.5-20.5 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 45*2 | 132 | 75×2 | 185 | 315 |

“Twenty years of technology accumulation, is your reliable choice.”

— DingBO,DBM