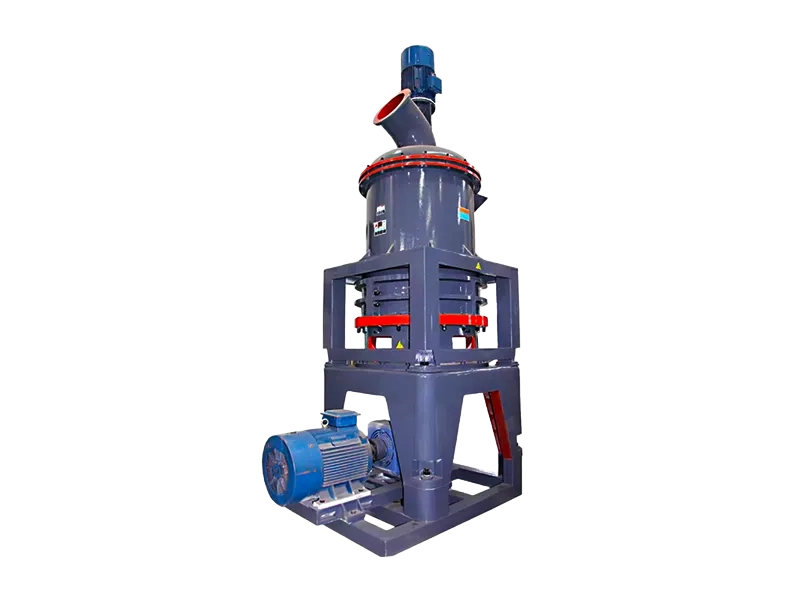

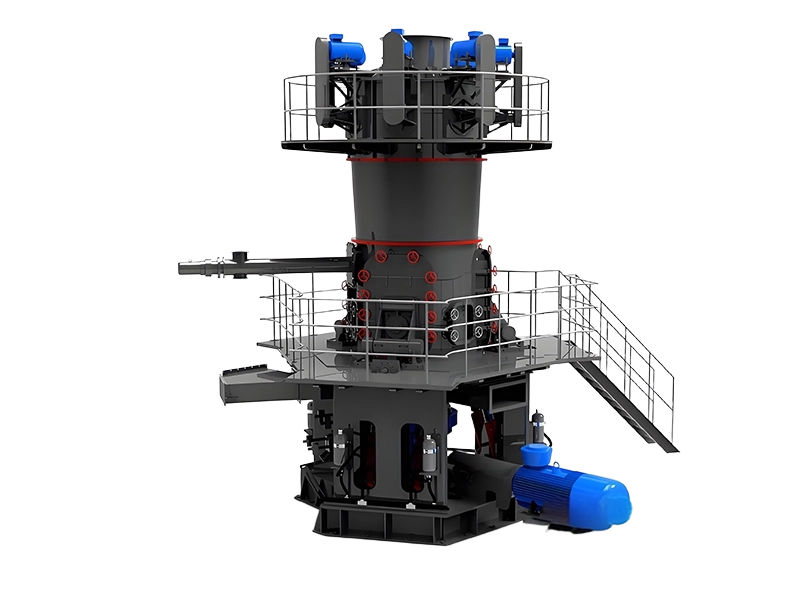

MDW European version grinding mill materials

MDW European version grinding mill is suitable for limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartz stone, bentonite and other materials.

MDW European version grinding mill application

MDW European version grinding mill is widely used in cement, new building materials, refractory materials, fertilizers, metal ore dressing, glass and ceramics, power plant desulfurization, non-metallic mineral powder making and building materials and chemical industries.

MDW European Type Grinding Mill Features

PC Coarse Powder Grinding Features

High efficiency and energy saving

Adopting advanced design and technology, the grinding efficiency is improved and the energy consumption is reduced.

Strong stability

Reasonable structural design, stable operation and low failure rate.

MDW European Type Grinding Mill Working Principle

- 1. Feeding: After the material is processed by the crusher, it is evenly and quantitatively fed into the grinding chamber of the mill through the variable frequency belt feeder.

- 2. Grinding: After the material enters the grinding chamber, it is gradually ground into fine powder by the high-speed rotation impact and friction of the grinding roller and the grinding ring.

- 3. Classification: The ground material rises with the airflow generated by the fan and enters the powder selector for classification. The powder selector screens the material according to the particle size, and the material with qualified fineness passes, while the coarse particles return to the grinding chamber for re-grinding.

- 4. Collection: The qualified fine powder after classification is collected by the cyclone powder collector to separate the air.

- 5. Discharge: The collected fine powder is discharged from the mill through the discharge device, completing the entire grinding process.

During the entire working process, the European version of the mill uses efficient air selection technology and precise classification system to ensure the grinding efficiency and fineness control of the material. At the same time, the internal thin oil lubrication system and dust removal device ensure the stable operation of the equipment and environmental protection requirements.

Technical Parameters

| Model | Feed Particle Size (mm) | Finished Product Particle Size (mm) | Production Capacity (t/h) | Main Motor Power (kW) | Fan Motor Power (kW) | Powder Selector Motor Power (kW) | Electromagnetic Vibrating Feeder Model | Electromagnetic Vibrating Feeder Power (kW) |

| MDW110 | <30 | 1.6-0.045, 0.038 | 3-9 | 55 | 55 | 7.5 | GZ2F | 0.15 |

| MDW138 | <35 | 1.6-0.045, 0.038 | 6-17 | 90 | 110 | 18.5 | GZ3F | 0.2 |

| MDW215 | <50 | 1.6-0.05, 0.038 | 15-45 | 280 | 315 | 55 | GZ5F | 0.65 |

| MDW198 | <45 | 1.6-0.05, 0.038 | 12-33 | 220 | 250 | 37 | GZ4F | 0.65 |

“Twenty years of technology accumulation, is your reliable choice.”

— DingBO,DBM