How To Make Gypsum Powder

Gypsum powder production line is the natural dihydrous gypsum ore (gypsum) or industrial by-product gypsum (desulfurized gypsum, phosphogypsum, etc.) through grinding mill and after a certain temperature heating calcination, so that the dihydrous gypsum dehydration decomposition, the generation of β semi-hydrous gypsum (CaSO4 1/2H2O) as the main component of the product, that is building gypsum.

Stone crusher breaks large size of gypsum ore into small particles less than 30mm, which are transported to raymond mill for grinding. After grinding, the gypsum powder reaching the required fineness of the product is sent to the boiling furnace for calcining by the separator. The coarse powder will be returned to raymond mill for grinding again until qualified. After calcined qualified gypsum powder into the clinker storage or into the product workshop for use.

Components of a Gypsum Grinding Mill Plant

1. Gypsum Crusher: Raw gypsum is first crushed into smaller particles by a crusher to facilitate the grinding process.

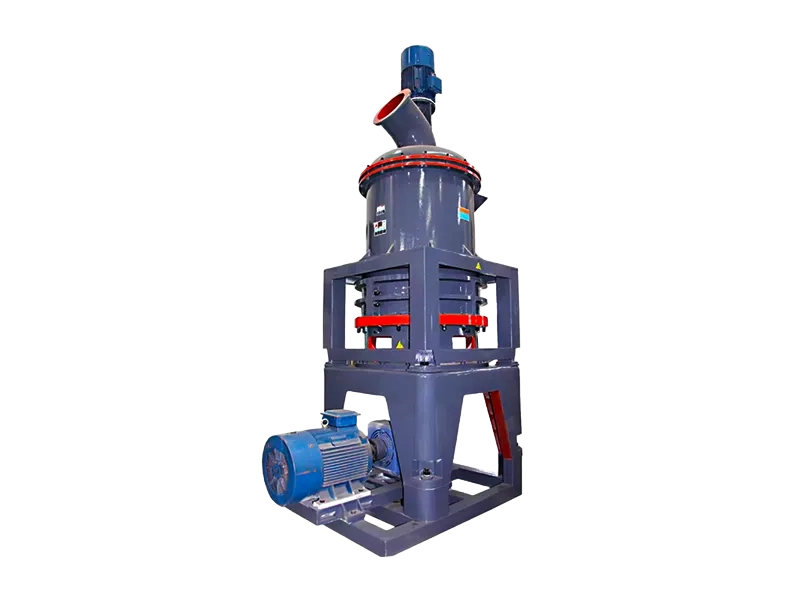

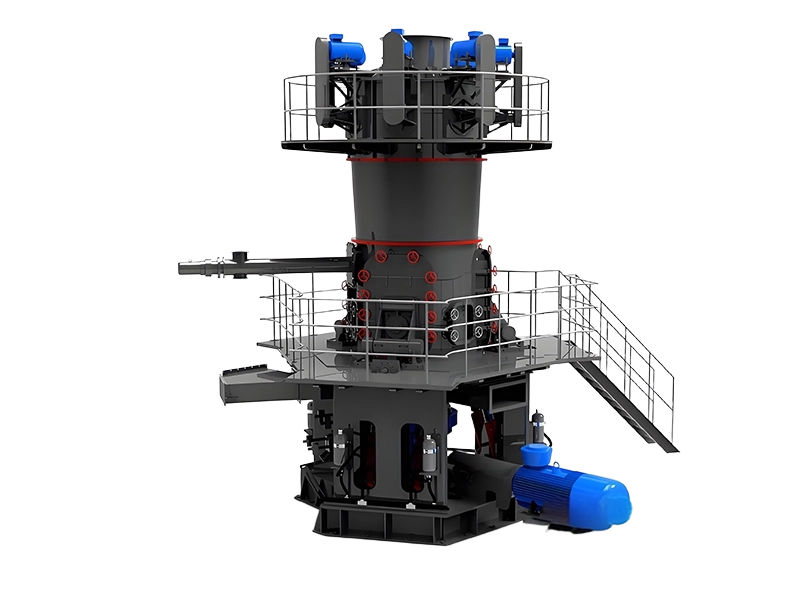

2. Gypsum Grinding Mill: The crushed gypsum is then sent to a grinding mill where it is ground into a fine powder. Common types of grinding mills for gypsum include ball mills, Raymond mills, vertical roller mills, and ultrafine mills.

3. Classifier: A classifier is often used to control the particle size distribution of the ground gypsum powder. It separates the fine particles from the coarse ones and ensures a consistent product quality.

4. Dust Collector:A dust collector is essential to collect and remove airborne dust generated during the grinding process, ensuring a clean and safe working environment.

5. Packaging Machine:Once the gypsum is ground to the desired fineness, it is packaged using a packaging machine for storage or transportation.

Gypsum Powder Manufacturing Process

Raw gypsum rocks are crushed by jaw crusher to the required sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding.

The grinding roller device in raymond mill chabmer rotates around not only the central shaft but also along the grinding ring,with the grinding roller rotating itself under the action of the friction. The grinding roller hanger has a shovel blade installed at the bottom of roller, the shovel blade and grinding roller throw up and feed the gypsum between the grinding rollers and ring, which will produce an outward centrifugal force ( an extrusion force ) to crush the materials.

The grinded gypsum powder are carried by the airflow from the blower to the classifier to be classified, the particles which meet the fineness(80-500mesh) enter cyclone collector through pipe, and are separated and collected there. They are discharged at the discharging valve to become finished gypsum powder; the airflow is sucked to the blower by return pipe on the top of cyclone collector.The whole raymond mill plant airflow system is a sealed circulation, and is circulated under positive and negative air pressure.