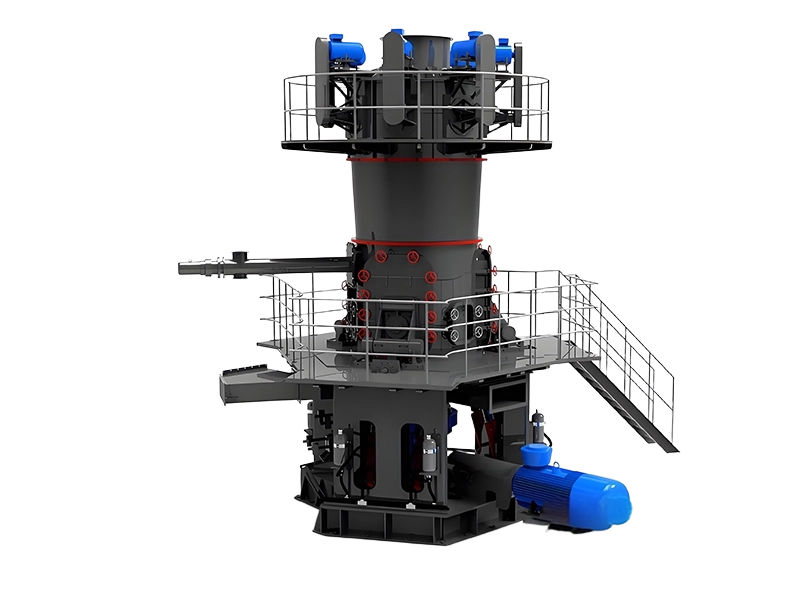

DBGM Vertical Roller Mill Materials

DBGM vertical roller mill is commonly used for grinding cement, slag, clinker, limestone, volcanic ash, calcite, talc, barite and other materials.

DBGM Vertical Roller Mill Materials Application

DBGM vertical roller mill is used in the fields of building materials, electric power, metallurgy, chemical industry, non-metallic minerals, environmental protection and new materials.

DBGM Vertical Roller Mill Features

High Efficiency

Using material bed grinding technology, the grinding efficiency is much higher than that of traditional ball mills.

Energy saving

Low energy consumption, saving more than 30% energy compared with traditional ball mills.

Easy to maintain

Simple structure, easy replacement of grinding roller and grinding disc, small maintenance workload.

DBGM Vertical Roller Mill Features

- 1. Material Feeding: The material enters the crushing chamber through the feed port.

- 2. Extrusion and Grinding: The grinding roller rotates under high-pressure gas, squeezing and rubbing the material on the grinding disc into powder or particles.

- 3. High-Speed Rotor: The rotor inside the equipment rotates at high speed, generating strong centrifugal force.

- 4. Impact and Crushing: The material collides with the impact plate fixed on the inner wall, causing an impact and crushing effect.

- 5. Particle Size Control: The required particle size is controlled by adjusting the discharge port and rotor speed.

- 6. Recirculation Effect: Part of the crushed material enters the chamber again for further crushing until the desired particle size is achieved.

- 7. Automatic Protection: The system automatically shuts down in abnormal situations to ensure safety for both the equipment and operators.

- 8. Closed-Loop Circulation: The process involves feeding, crushing, screening, wind conveying, and finished product discharge, continuously crushing the material until the required particle size is reached.

Technical Parameters

Dingbo vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizes.| Model | Yield (t/h) | Grinding Plate Diameter (mm) | Grinding Path Diameter (mm) | Material Moisture (%) | Raw Material Fineness (%) | Raw Material Moisture (%) | Main Motor Power (kW) |

| DBGM1300 | 20-25 | 1870 | 1300 | <10% | R0.08≤12% | ≤1% | 200 |

| DBGM1500 | 26-34 | 2180 | 1500 | <10% | R0.08≤12% | ≤1% | 280 |

| DBGM1700 | 40-50 | 2400 | 1700 | <10% | R0.08<12% | ≤1% | 400 |

| DBGM1900 | 60-70 | 2680 | 1900 | <10% | R0.08<12% | ≤1% | 500 |

| DBGM2200 | 85-110 | 2900 | 2200 | <10% | R0.08<14% | ≤1% | 800 |

| DBGM2400 | 95-130 | 3140 | 2400 | <10% | R0.08<14% | ≤1% | 900 |

| DBGM2800 | 120-160 | 3300 | 2800 | <10% | R0.08<14% | ≤1% | 1250 |

| DBGM3400 | 190-240 | 4560 | 3400 | <10% | R0.08<15% | ≤1% | 1800 |

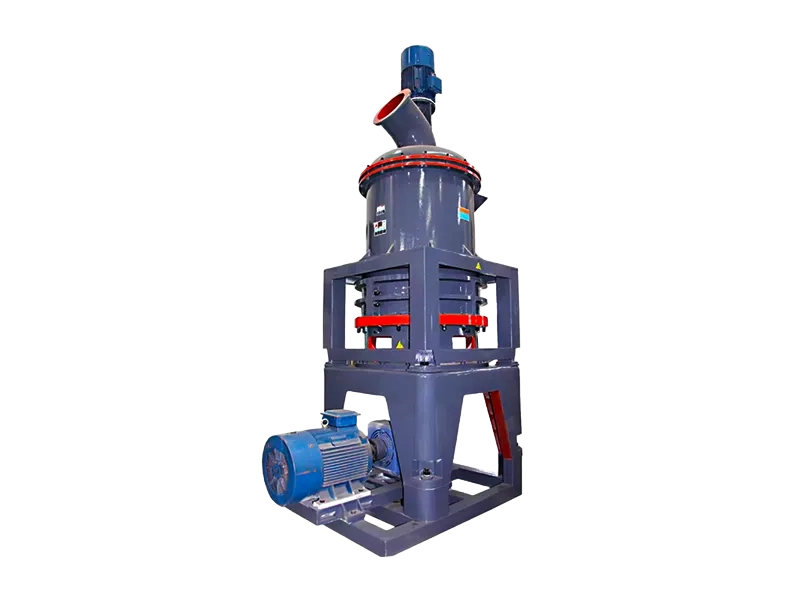

Vertical Coal Mill Technical Parameters

Vertical coal mills are used for grinding bituminous coal, anthracite and petcoke for the burning systems in clinker burning and power generation according to the type and quantity of additives.Note: Raw coal size 40~50mm, feed moisture ≤15%, final product moisture ≤1.0%, final product finenessR80μm=10%~12% (bituminous coal), R80μm=1%~3%(anthracite), coal grindability HGI=40~70.

| Model | Capacity (t/h) | Grinding Plate Diameter (mm) | Grinding Path Diameter (mm) | Maximum Feed Size (mm) | Raw Coal Moisture (%) | Coal Powder Fineness (%.R0.08) | Coal Powder Moisture (%) | Main Motor Power (kW) |

| DBGM800M | 5-8 | 1100 | 800 | 25 | <10 | 5-12% | ≤1% | 110 |

| DBGM1100M | 7-12 | 1520 | 1100 | 25 | <10 | 5-12% | ≤1% | 132 |

| DBGM1300M | 10-15 | 1870 | 1300 | 25 | <10 | 5-12% | ≤1% | 185 |

| DBGM1500M | 16-22 | 2180 | 1500 | 30 | <10 | 5-12% | ≤1% | 250 |

| DBGM1700M | 20-28 | 2400 | 1700 | 30 | <10 | 5-12% | ≤1% | 315 |

| DBGM1900M | 26-35 | 2680 | 1900 | 35 | <10 | 5-12% | ≤1% | 400 |

| DBGM2200M | 40-45 | 2900 | 2200 | 40 | <10 | 5-12% | ≤1% | 500 |

“Twenty years of technology accumulation, is your reliable choice.”

— DingBO,DBM