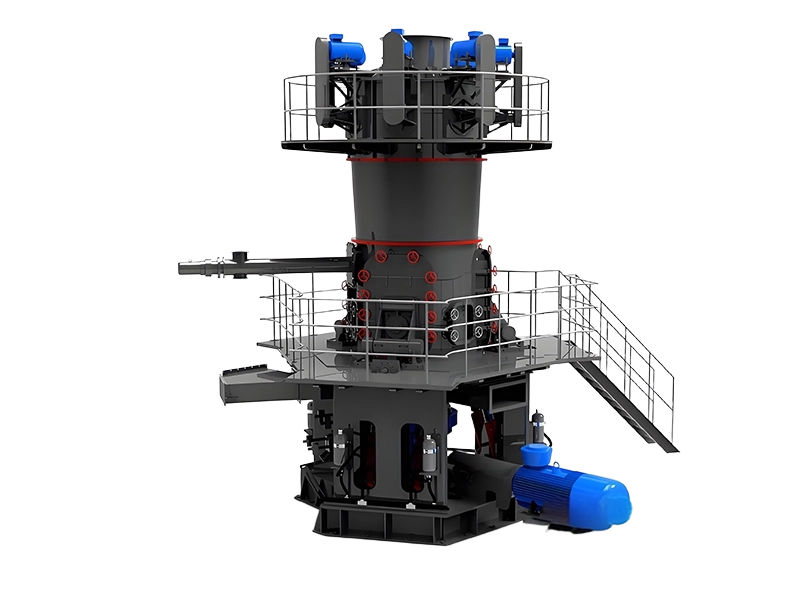

There are two types of ball mill (also called cement mill) plant process: closed-circuit system and open circuit system. We use the new type closed-circuit system as the standard because it is more energy-efficient and can grind different types of cement.Cement grinding mill plant includes cement roller press, cement mill, cement seperator, dust collector, conveyor and other cement equipment.

1.In the roller press cement pre-grinding part, the fine power ground by roller will be sent to ball mill for further grinding. In a closed-circuit system, coarse particles are separated from finer product and return to ball mill for further grinding, making over-grinding unnecessary.

2.Cement ball mill is to grind and mix clinker with other aditives such as gypsum, slag, flyash etc. The cement mill is a big consumer of electricity, so in order to reduce power consumption, it is a good option to install roller press to reduce the particle size of the material before entering the ball mills.

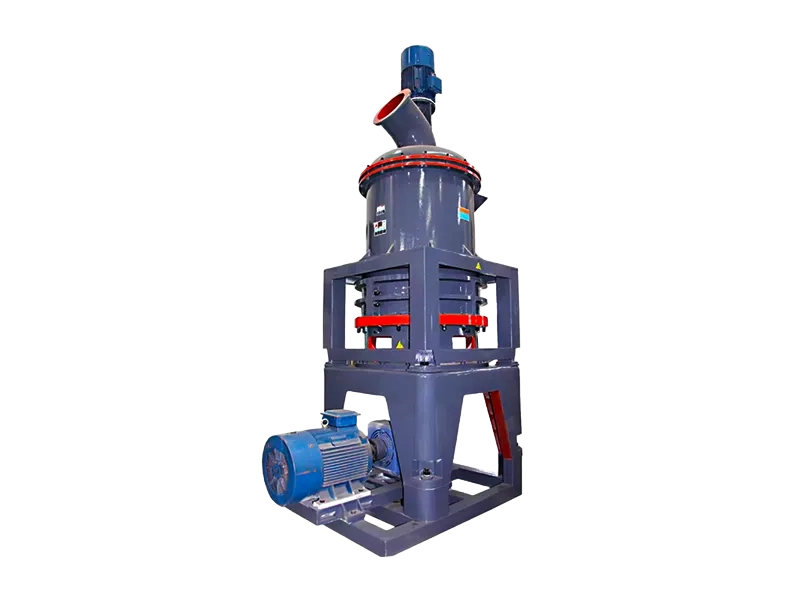

3.The essential equipment of this closed-circuit grinding system is a cement classifier, also known as a cement separator. It is to select the required cement powder in time and send the much coarse cement powder back to the grinding mill for regrinding, making sure the uniform particle size.

4.Dust collector is to collect raw powder or finished cement. It is high dust removal efficiency and good sealing effect, improving working conditions and preventing air pollution.

5.The final cement packing could use cement packaging machine or build a finished product bin for the bulk system of cement tankers.