Processing materials: Limestone, calcite, dolomite, barite, talc, gypsum, etc

Configuration: Crusher machine, grinding mill, air classifier, dust collector, packing machine, etc

Application: Chemical, mineral, metallurgy, paint, ceramics and other industries

Calcium carbonate plant is also known as calcium carbonate processing or grinding plant. It is a production line where ground calcium carbonate powder are made mechanically in factories.

With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world. As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the world.

What is calcium carbonate Manufacturer?

Calcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or marble. Usually there are a complete set of machinery needed for the calcium carbonate production line.

And some calcium carbonate manufacturing plants are also equipped with calcium carbonate coating machine, so that both natural coated and uncoated calcium carbonate powder can be obtained.

There is no one-for-all solution for building a calcium carbonate production plant. For customers need to consider various requirements in powder fineness, production capacity and so on.

Calcium carbonate manufacturing process

At first, the raw materials, such as limestone, calcite and marble are mined from the quarry. Then these raw material slumps are carefully selected, washed to ensure the high quality of finished calcium carbonate powder. And then these dried and cleaned raw materials will go through first and secondary crusher, such as jaw crusher and hammer crusher, to become the required feed sizes.

At this time, these materials are ready for further grinding. Firstly, the raw material is put into feed silo, from which raw material is transported to the ball mill through vibrating feeding device. In the ball mill, with the impact of media balls, these raw materials are ground to fine calcium carbonate powder.

And then the materials from the ball mill will be blown through classifier. The required fine ground calcium carbonate powder will be delivered to the product silo, while the coarser material will be returned to ball mill for regrinding. And the final product will be packed and stored for usage.

Of course, except the core machine such as grinding mill, classifier, there are also other transporting system, dust collector system, and packing systems. Besides, the whole calcium carbonate production process can be fully automatic and be controlled by operation panel.

Features of Dingbo calcium carbonate plant

Tailored turnkey solution. Dingbo specializes in designing and engineering calcium carbonate processing line. And we also provide a complete set of equipment to meet customer’s needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications and etc.

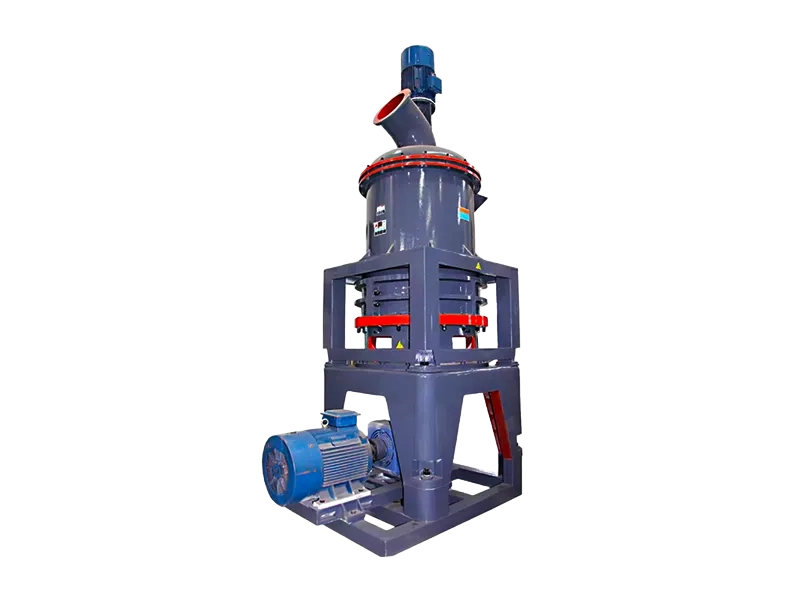

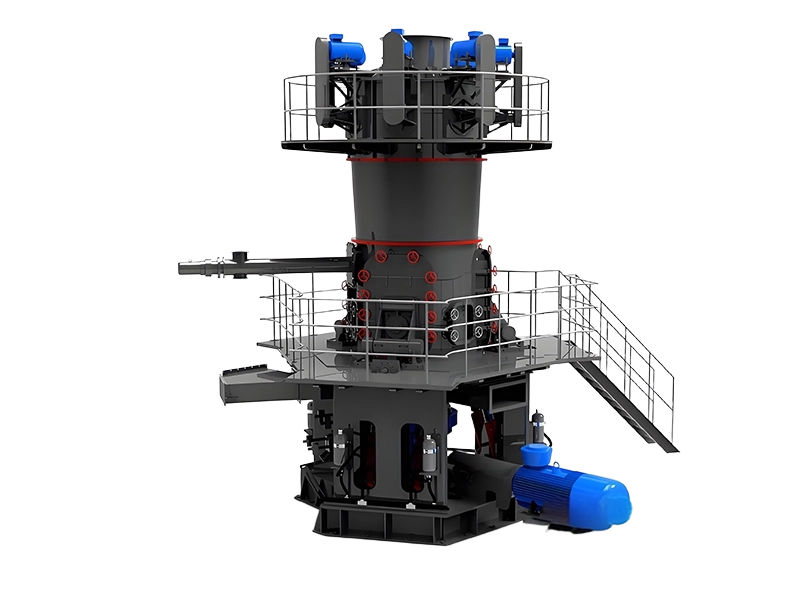

Controlled calcium carbonate particle size. Dingbo machinery company provides tailored solution for calcium carbonate grinding plant to meet customer’s various needs. The core part of calcium carbonate plant, the grinding mills of Dingbo, whether ball mills with classifier or wet grinding mills, can produce ground calcium carbonate powder in various particle sizes from fine to ultra fine GCC powder.

Various calcium carbonate powder production capacity available. According to customer’s needs, Dingbo can offer you tailored solution with different calcium carbonate production capacity. A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications.

Both dry grinding and wet grinding are available. Grinder or grinding mill is the core equipment for calcium carbonate grinding plant, which can largely determine the fineness of the end product. Dingbo mainly provides ball mill combined with classifier and vertical wet mixing grinder.

PLC control system. The PLC system can help you monitor the whole calcium carbonate production line and adjust the materials and so on.

Automatic calcium carbonate production line available. Fully automatic calcium carbonate plant can ensure the efficiency as well as reduce the labor costs.

A full set of machinery. Dingbo supplies the complete set of equipment for the calcium carbonate plant, from crushing machine, transporting system to grinding mill, classifier, packing machine as well as optional coating machine.

High quality final product. With high quality raw materials, Dingbo can provide quality tailored system that produce uniform ground calcium carbonate with high brightness, large surface area, high stability and required fineness. Final ground calcium carbonate powder can be used in paper, plastic, paint and other industries.

Environmental consideration. As for the dust produced from the calcium carbonate manufacturing process, Dingbo supplies de-dusting and other equipment.